Client Name: Confidential (Major U.S. potato processor)

Industry: Food Processing / Frozen Foods

Location: Washington State

Project Scope: Redesign a water-reclamation system to improve efficiency, reduce wastewater output, and support sustainability initiatives.

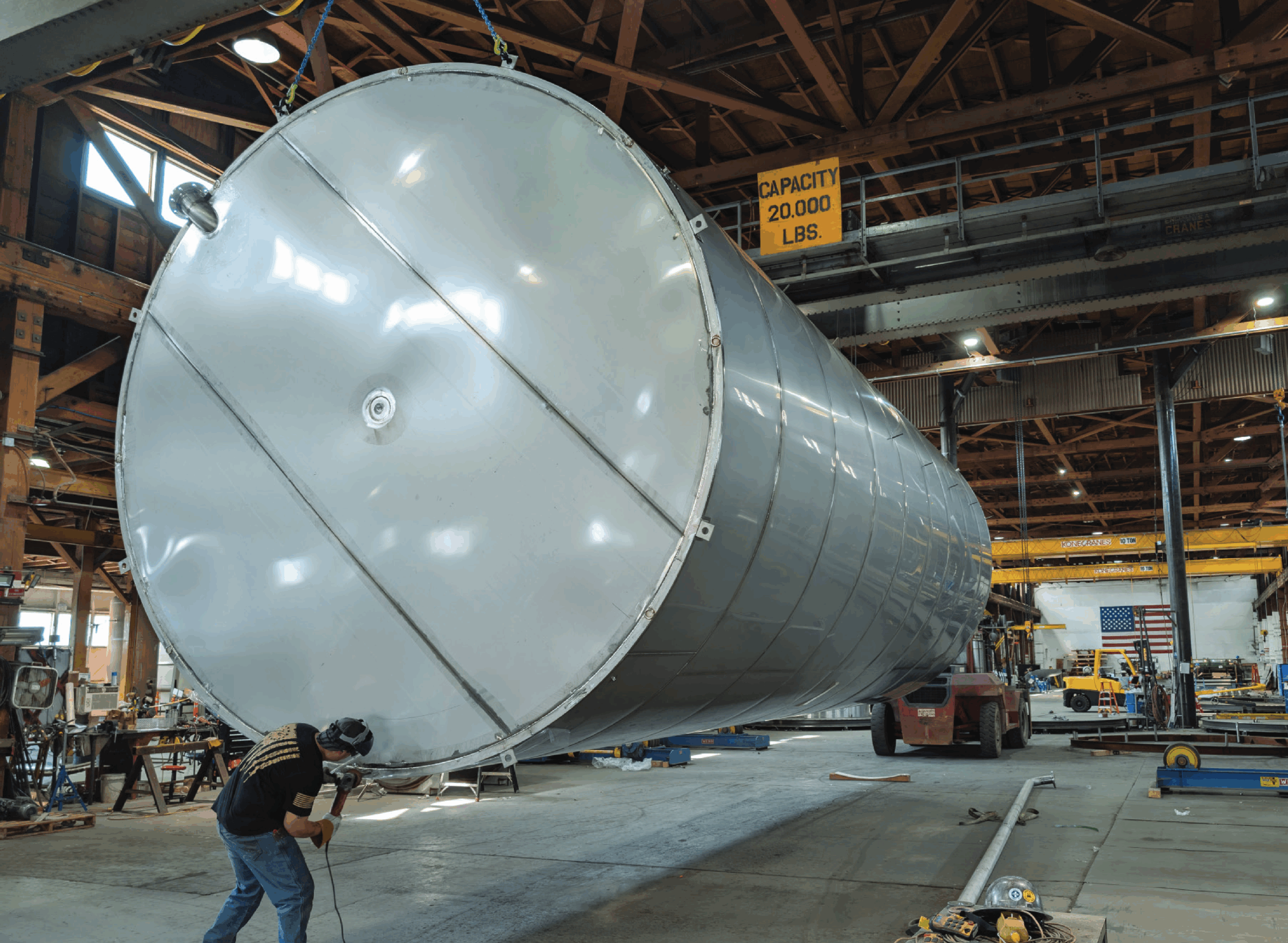

Solution Provided: Spokane Stainless Technologies engineered and delivered a custom-built, 40,695-gallon insulated water-reclamation vessel integrated into a new, closed-loop processing system.

The processor—supplying major fast-food chains like McDonald’s, Burger King, and Wendy’s—relied on a system that couldn’t efficiently separate starch, oils, and organic material from wastewater.

High water consumption, rising operational costs, and limited reuse potential made the process unsustainable.

A previous third-party modification of SST equipment created more problems than it solved. To achieve real improvement, the company needed a purpose-built solution designed in direct collaboration with SST.

SST engineers approached the project as process partners, conducting a full system review and designing a custom 40,695-gallon potable-water tank featuring:

Cone-top and sloped-bottom for efficient drainage

Dual manways and multiple access ports

Two-inch Rockwool insulation with 14-gauge stainless cladding

Fully welded, passivated stainless construction for sanitation

Integrated sensors for precise temperature and level monitoring

This vessel became the core of a new reclamation system that turned wastewater into a reusable process resource.

Key performance indicators highlighting project success:

Substantial reduction in total water consumption through on-site recycling

Lower wastewater management and treatment costs

Improved environmental-compliance metrics

Enhanced sustainability reporting at the corporate level

Elimination of problematic third-party system modifications

Streamlined maintenance and simplified operator workflow

The success of this initiative has since expanded into a broader facility-wide sustainability program, with SST continuing as a strategic engineering partner for new process-efficiency projects.