An ASME vessel is a pressure vessel designed and fabricated to the standards set by the American Society of Mechanical Engineers’ Boiler and Pressure Vessel Code.

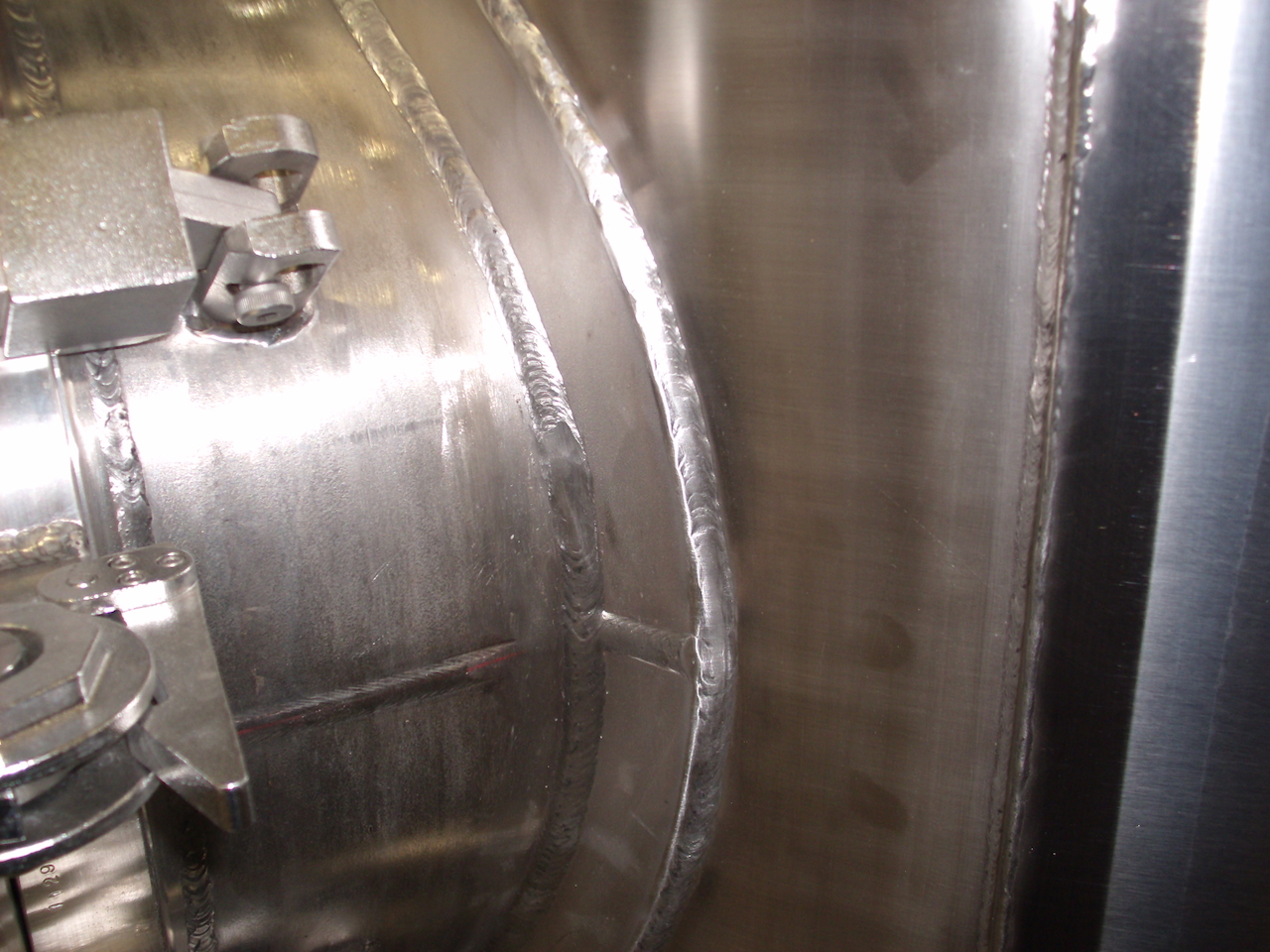

The ASME stamp represents a chain of accountability: third party inspection, material traceability, qualified welding procedures, and design calculations verified by licensed engineers.

These vessels operate across pharmaceutical production, food and beverage processing, water filtration, and chemical handling — applications where failure isn’t an option. They rarely make headlines, but in facilities where regulatory scrutiny is constant and operational continuity is everything, ASME vessels are critical in keeping processes running.

Where ASME Vessels Quietly Power Essential Operations

ASME-certified vessels operate across industries where precision, safety, and regulatory compliance are foundational. While the applications vary, the underlying requirement is the same: equipment engineered to perform reliably under pressure, with documentation that proves it.

Pharmaceutical Manufacturing

In pharmaceutical environments, contamination isn’t an inconvenience—it’s a batch loss or recall. ASME vessels provide the structural integrity and material traceability that cGMP compliance demands. Pressure ratings matter when processes involve sterilization, vacuum transfer, or pressurized filling.

Food and Beverage Processing

From dairy processing to beverage production, ASME-certified stainless steel tanks maintain product integrity under thermal and pressure stress. FDA requirements for food-contact surfaces pair with ASME fabrication standards to create equipment that satisfies both safety and sanitation audits. Seasonal production surges demand vessels that perform consistently without degradation.

Water Filtration and Treatment

Municipal and industrial filtration systems rely on pressure vessels that maintain structural integrity across thousands of operating cycles. ASME certification ensures vessels handle the pressure differentials inherent in filtration processes. Long service life reduces replacement frequency and system downtime.

Chemical and Industrial Processing

Corrosive environments demand vessels built with materials and welds that won’t degrade under chemical exposure. ASME standards include material specifications that account for these stresses. The safety margins built into certified vessels protect both personnel and facilities.

The Stainless Steel Advantage in ASME Vessel Fabrication

While ASME certification addresses design and fabrication standards, material selection determines long-term performance. Stainless steel remains the industry standard for pressure vessels in regulated environments—not by tradition, but by capability.

- Corrosion Resistance: Stainless steel’s chromium oxide layer provides inherent protection against rust and chemical attack. This is critical for vessels handling aggressive media or operating in washdown environments.

- Durability and Service Life: Stainless steel ASME vessels are engineered for decades of service, not years. Reduced replacement frequency means lower total cost of ownership despite higher initial investment.

- Sanitation and Cleanability: Smooth, non-porous surfaces resist biofilm buildup and simplify CIP (clean-in-place) protocols. Essential for pharmaceutical, food, and beverage applications where contamination risk must be minimized.

- Temperature and Pressure Performance: Stainless steel maintains mechanical properties across wide temperature ranges. Combined with ASME design standards, this creates vessels that perform reliably under thermal cycling and pressure fluctuations.

- Regulatory Alignment: Stainless steel is the material of choice for FDA, 3-A, and other regulatory frameworks. Pairing stainless construction with ASME certification creates equipment that satisfies multiple compliance requirements simultaneously.

What to Look for in an ASME Vessel Partner

Not every fabricator with an ASME stamp operates the same way. When evaluating partners for custom vessel work, a few factors separate fabricators who treat certification as a credential from those who treat it as a discipline.

Look beyond whether a fabricator holds an ASME stamp—consider which stamps they maintain. U stamps for pressure vessels, UM for miniature vessels, R stamps for repairs. National Board registration ensures vessels can be legally installed and insured across jurisdictions.

Custom applications require partners who can design to your specifications, not fabricators limited to adapting generic templates. The conversation should feel like collaboration, not constraint.

A fabrication partner should make your compliance conversation easier, not harder. Comprehensive documentation packages—material test reports, weld maps, inspection records—matter when auditors arrive.

Vessels have long service lives; your fabrication partner should too. Consider whether the partner offers inspection, repair, and modification services for equipment already in the field.

Spokane Stainless Technologies ASME Vessel Capabilities

Spokane Stainless Technologies designs and fabricates ASME-certified stainless steel vessels for operations where reliability and compliance are foundational. We maintain ASME U, UM, and R stamps along with National Board registration—the certification depth that regulated industries require.

From pharmaceutical processing to food and beverage production, filtration systems to chemical handling, our engineering team works with clients to specify vessels engineered for their actual applications—not adapted from generic designs.

From initial design through decades of service, SST supports operations that can’t afford equipment that merely “meets code.”

Contact our team to discuss your application requirements and compliance needs—we’ll help you specify a vessel engineered for lasting performance.